materials:

1" x 2" x 1/8" rectangular aluminum tube

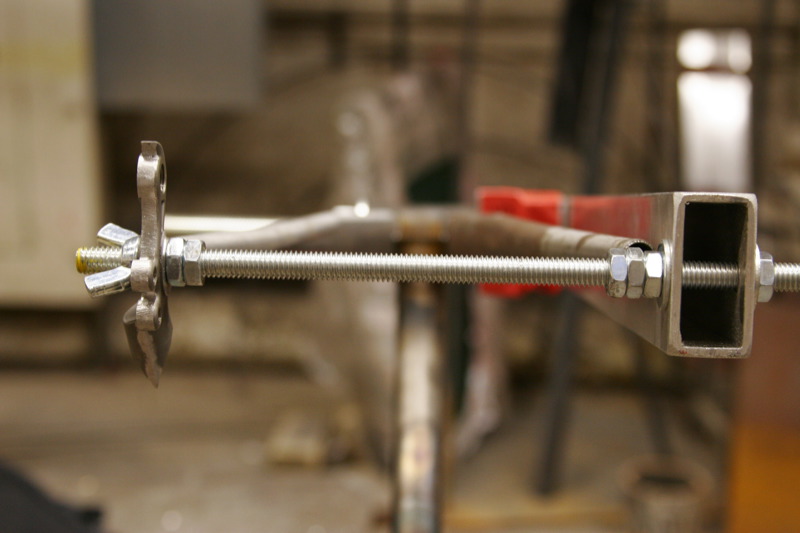

3/4" x 12" threaded rod, two washers, two nuts

3/8" x 12" threaded rod, various nuts and washers

two old BB cups, English thread, with a 3/4" hole through the middle

a little red tape

metric calipers are also necessary

i used a drill press, a bunch of layout tools, a 3/4" hole saw, and a 3/8" twist bit to drill holes perpendicular to the wide face and in line with one another, with the holes' centers 450 mm from each other.

tilt your head to the right, please. flickr is being weird.

the 3/4" threaded rod runs through the two old cups threaded into the BB shell. the part covered in red tape is a pair of spacers taped together, made from the same aluminum as the big beam. the dummy axle is 3/8" rod.

the spacers are needed because if the big alu piece was referenced right against the shell, there would be no room for the chainstay.

i measured the spacer block with calipers. to position the dropouts, i take half the BB shell width (68 mm, so half is 34 mm), add the width of the spacer (51.2 mm), and assume the inside face of the big alu piece is that distance from the frame's centerline. from there i use math, lock nuts, and washers to position the dropouts at the proper distance from the alu's inside face and at the proper distance from one another.

plusses:

-locally available materials, possibly excepting the alu tube, which i bought from an online metals dealer, the name escapes me

-pretty cheap. nuts and bolts were $15 or $20, alu was like $40 for 8 ft. with shipping.

problems:

- the 3/8" rod is rather flexy, so don't count on it to read identically across its whole length. a solution would be another, identically machined alu tube on the BB shell's other side. or just check each chainstay's miter with the jig mounted on each side, to double-check.

- getting the spacing right on the dummy axle is tricky and time-consuming. i had to grind down a nut to get it close on one side.

- to work well, the chainstays need to be mitered, which isn't convenient if you're trying to use it to miter chainstays.

- only good for one chainstay length. change the 3/8" hole to a milled slot for more versatility, although that might present problems with accuracy.

- i dunno how well it actually works yet.

please modify and improve at will, but email me pics of your creation.

1 comment:

You can get various sizes of Al tube stock in small quantities for reasonable prices at http://www.smallparts.com/ I bought a 12" length of 1.25" square Al tube for under $10 (using it to make a LED bike light housing).

Post a Comment